R & D capabilities

Mold development

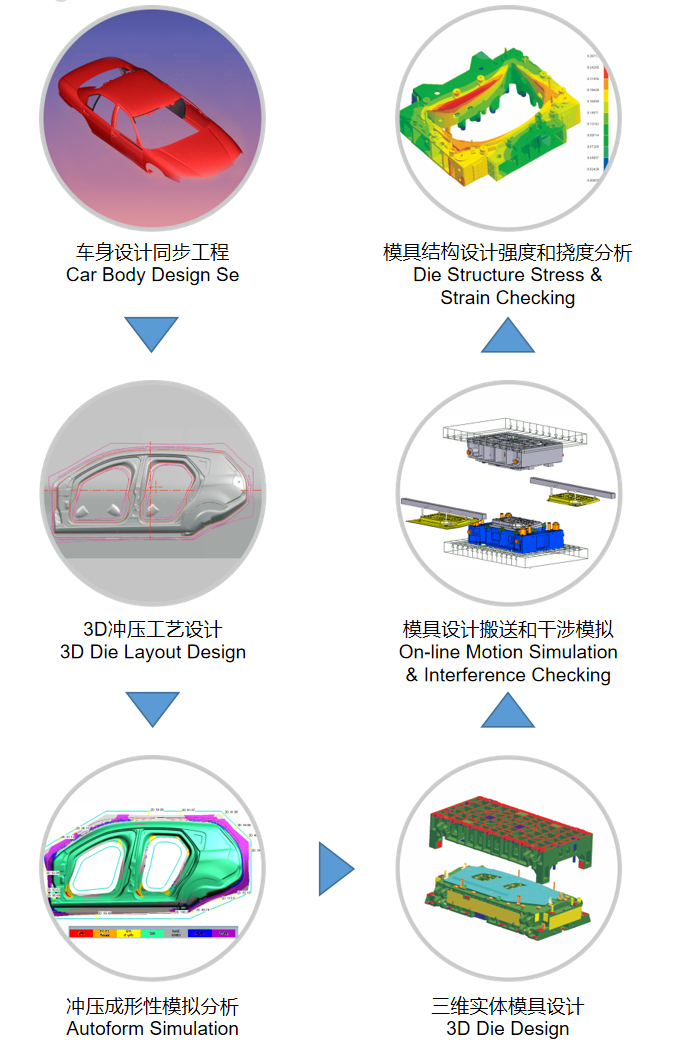

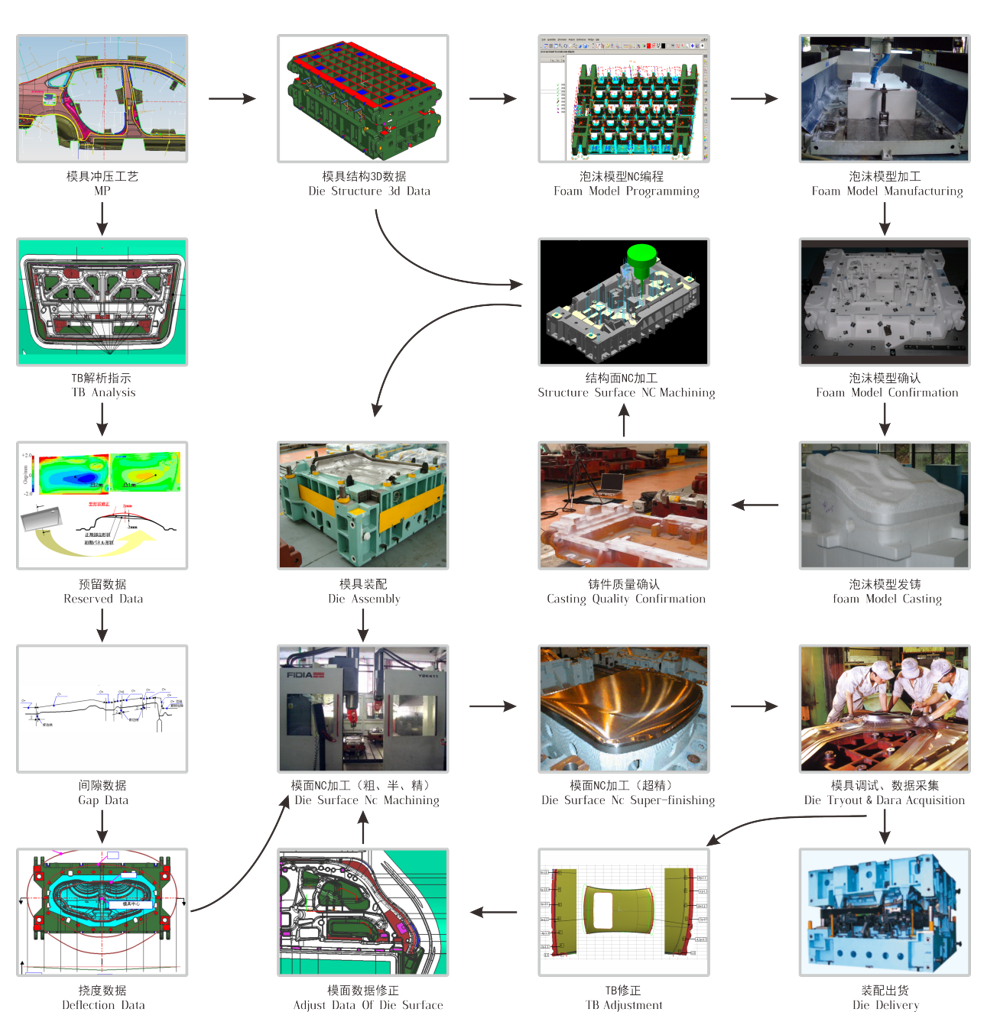

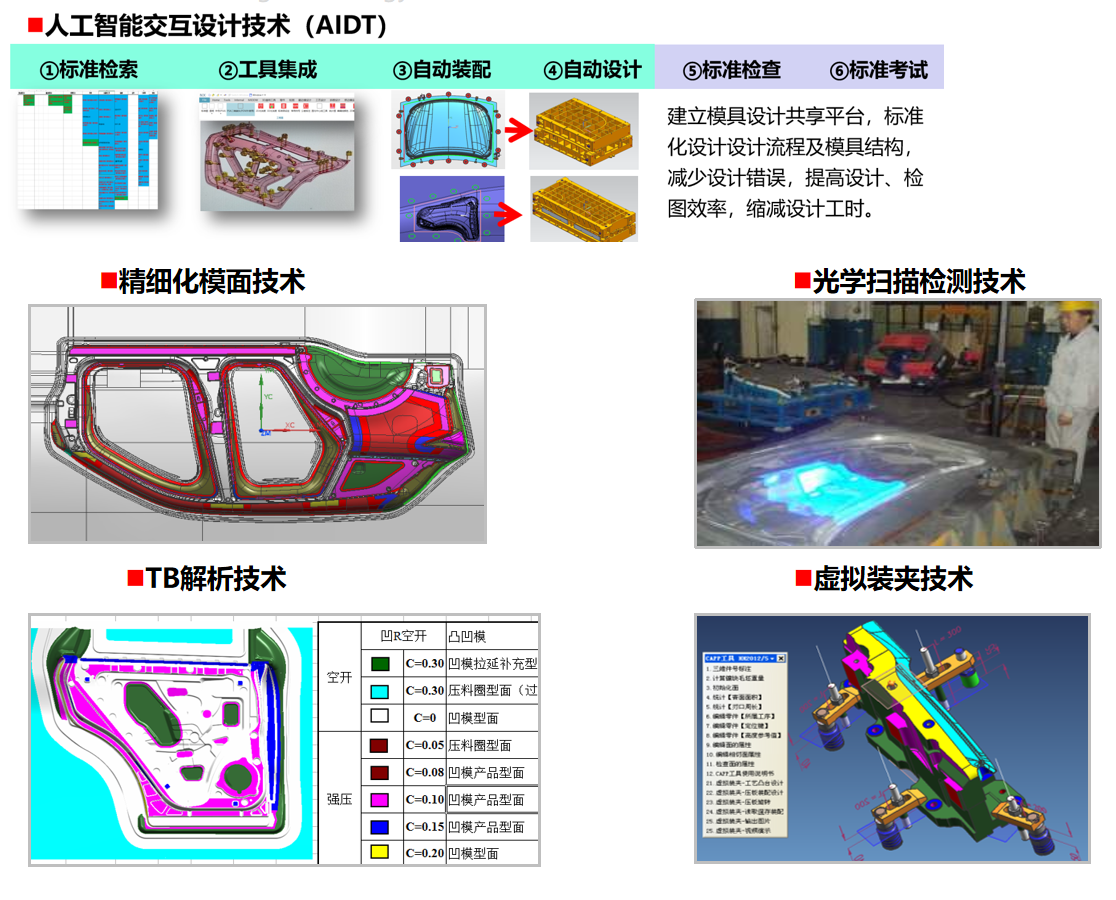

Regarding stamping dies business, DFDS adopts “To be the BIW development center of Dongfeng Motor Company” as its vision. There are more than 200 employees with expertise and experience in engineering technology and project management to give technical advice in die developing of automotive production, RFQ SE engineering, developing and manufacturing of inner and outer cover panels. We have strong technical capabilities of stamping process design and simulation of outer cover panels. We have set up complete 3D physical structure design standard and standard parts database, we can provide testing for parts transfer and dies static and dynamic interference , simulation analysis for dies rigidity and flexibility. We have developed TB analysis technique which can provide refined adjustment for reserving data, gap data and flexibility data of die-face data, it can also realize prediction for face A defects and spring back treatment to reduce manufacturing cycle of stamping dies and increase quality of stamped parts.

Die Design R&D Team

This team has the stamping die development capacity of all the 17 typical outer automotive body parts of whole-vehicle. It attend the simultaneous engineering development activity at least 7 new vehicles and modified vehicle annually. It has the development experience of process design,simulation,and die design of bodyside and fender for more than 30 cars. It is capable of predicting and correcting of stamping defects such as spring-back and A-class surface defect. It also has the ability of designing aluminum part process. This team is making outstanding contribution to Dongfeng group OEMs by shortening development cycle, increasing material consumption ratio and reducing operation number of process.

Die Design R&D Team

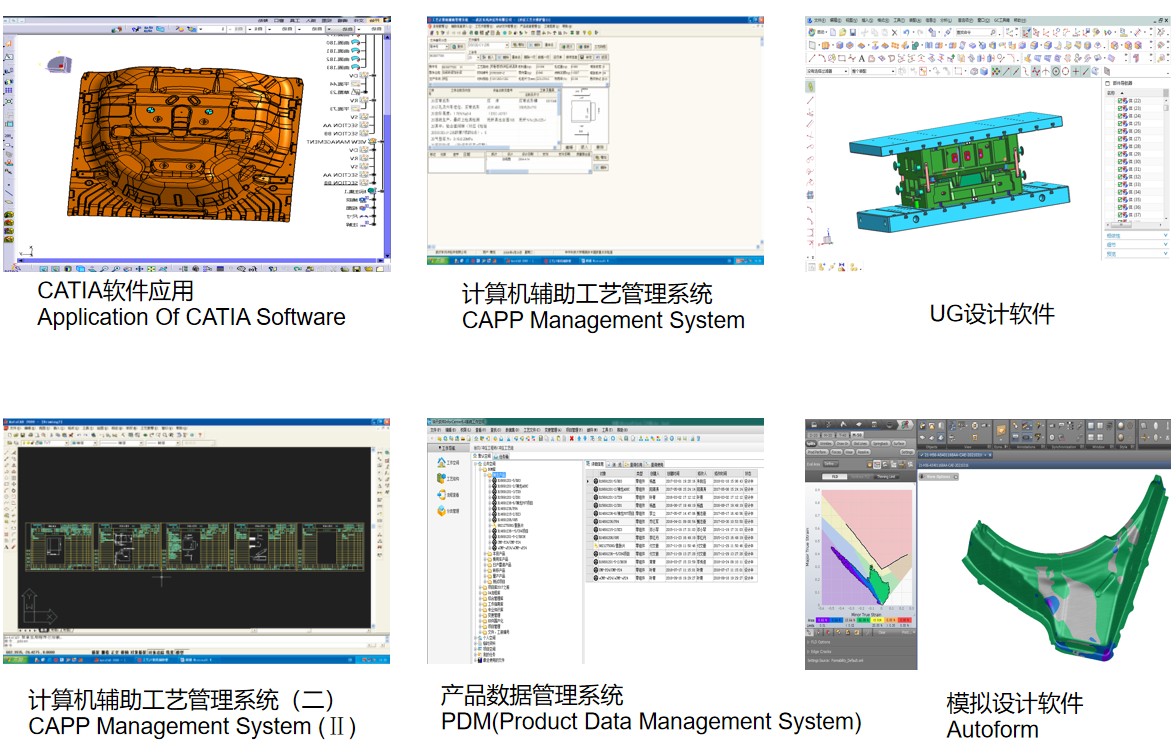

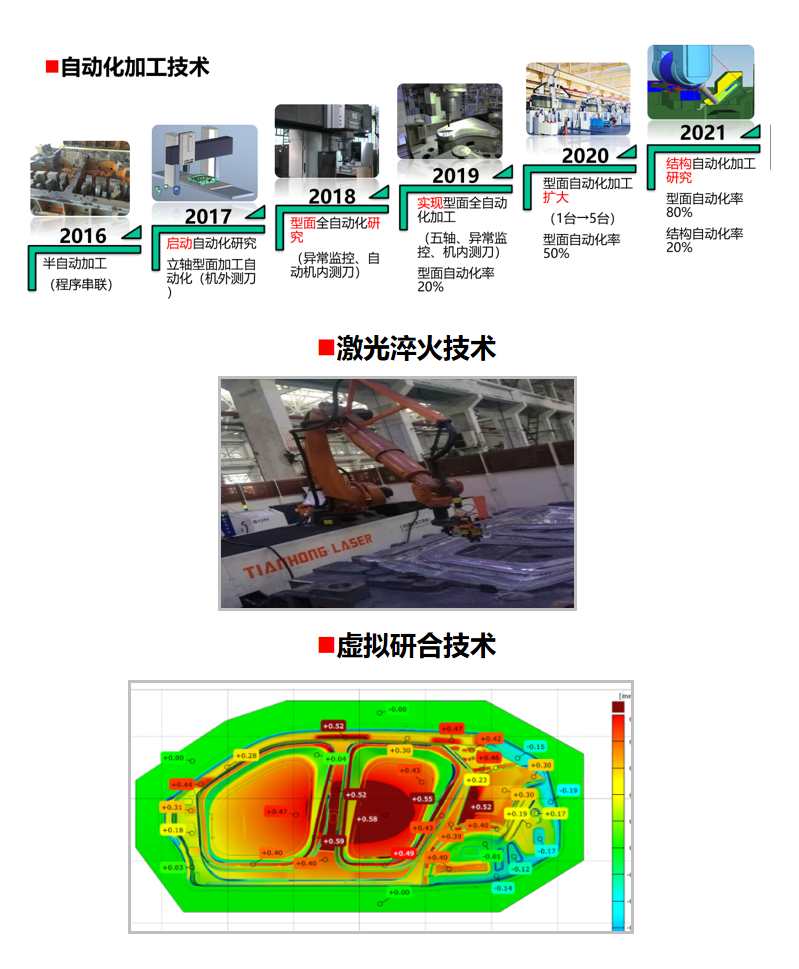

This team has developed and applied CAPP engineering setup system, extensively realized the integration , informatization, standardization, routinization and professionalization of manufacturing process and NC program ; they align themselves with the benchmark of front-line manufacturing techniques, extensively push and implement automatic NC machining technique, layered clean-up technique, toolpath optimization technique, refined die-face styling technique, concave-R dodging technique, laser quenching technique and Blu-ray scanning technique, etc.

Stamping Dies Quality Assurance Team

By implementing individual-operation self-controlling inspection and dedicated critical-milestones quality control , we realize whole-process quality assurance , we also effectively adopt variety of quality management means such as Q-up quality improvement, QRQC quick response, TB-analysis team solution and phased objective audit to ensure high quality of the parts .

Stamping Dies Project Management Team

This team is capable of making detailed project schedule monitoring plan, carrying out whole-process visualization management, they implement weekly analysis and then provide corrective actions accordingly, regularly communicate with customers to ensure project being on track, they have the right of utilizing and allocating all the resources available in company and the responsibility of guaranteeing project schedule.

Die Manufacturing Processes

Advanced Manufacturing Technology

Development of stamping welding

Cost-Focused Quality-First

Regarding stamping & welding business, DFDS adopts “to be the stamping & welding center of Dongfeng Moter Company” as its vision. There are more than 150 employees in engineering technology、project management and quality control? to ensure the programs of the customers. Labs in technology research of stamping process、 automatic stamping、welding and hot stamping had been established to provide over-value service. We took an active part in simultaneously development, meanwhile supply the best stamping & welding process plan and comprehensive solutions in logistic and package.

Complete Technical standards and product quality control system

Rich experience on stamping & welding parts development and manufacture

Good command at CAD、CAE、CAPP、PDM、3DCS and other software

IBM 3D workstation with CATIA software

Close cooperation with the first-rate die manufacturers home and abroad

Perfect inspection and test means, complete and efficient product development system

R&D team of Technology Department

R&D of Stamping & Welding